Okay - I'll start this off by pointing out that this isn't exactly going to be a typical retro-grouchy, vintage-bikey kind of post. There won't be any pictures of lovely old bicycles, or photos taken from bike riding adventures. There won't be any grumbling about modern bike tech, or nostalgia for the beautiful simplicity of vintage bikes. But there is some connection to my usual retrogrouch interests.

My now-teen-aged Retro-kid is an art student in high school, but so far has not learned how to do silk-screen printing at school. Silk-screening is something that I did many years ago and enjoyed, and she's expressed an interest in learning, so we decided to do a project together before our summer break ends.

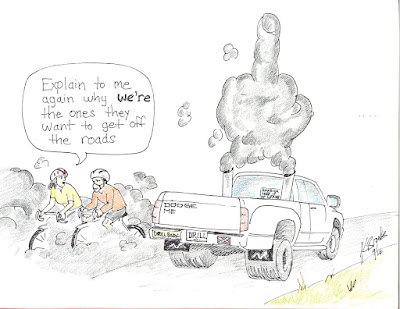

Some time back, readers might recall I posted about an old bike "safety" manual from the 1950s. If the children who were given these manuals learned anything from them, the main lesson would be "Don't Ride a Bike or You Will Die."

My daughter was looking through the old safety manual and we were both getting a good laugh out of it. She found one panel in particular that she found especially ridiculous and said "We should put this on a t-shirt." There you go - the genesis of an idea.

The kid just looks so smug as he heads to his (apparently) impending death

I looked the image over, and thought it might work okay for screen printing. For one thing, it's all "one color" - black on white, which is needed for reproduction on the screen and ideal for a "first time" project (if you have a multi-color image, you need a separate screen for each color - then you need to make sure all the colors line up in the final print!). However, there are "shaded" areas in the original artwork which can potentially pose a complication. They're done with a "half-tone" process (that's the pattern of little tiny dots, which you'll also see in newsprint photos) which should transfer OK on the screen - but when inked up and printed onto fabric they would create a muddle in the final result. So I cleaned up the image with some photo editing software, and while I was at it, I enlarged the text to a size that would show up much better when printed on fabric. I also enlarged the whole image to a good size for what we wanted, and printed it off with our basic home printer. The next step was to take the printed image over to the local copy center to have them turn it into an acetate transparency.

(image cleaned up, with larger text)

We also needed to make a trip to the art supply store to get a screen printing photo-emulsion kit, along with a fine mesh polyester screen (actual silk screen is rare these days), a squeegee, and some inks. We would also need a good shop lamp with 150 watt bulb, which I already had.

There are a few methods for creating silk screens, but the "photo-emulsion" method gives the most accurate transfer, and is what most professionals use. One nice thing is that, for beginners, there are pretty detailed instructions in the box.

We temporarily converted my bike workshop area in the basement into an art studio/darkroom - by covering the room's one window with cardboard, turning the workbench into an exposure area, and creating a makeshift drying rack over in the corner. I suppose at this point I should explain briefly that one thing about doing the photo emulsion process in screen printing is that it's a lot like photography. It uses light sensitive materials to transfer the image to the screen, which in turn creates a very detailed "stencil" which can then be used to print the t-shirts (or whatever you happen to want to print your design onto). Creating the "darkroom" isn't quite as demanding as with film photography, however, where every last bit of light has to be painstakingly "sealed out," because the light sensitivity of the materials is much less than with film. When working with film, even the slightest crack of light coming in from under a doorway can ruin the film. But with the silk screening process, a few cracks of light won't do much harm.

The kit shown above primarily consists of a 2-part chemical mixture: a large bottle with an emulsion (it looks a bit like blue Elmers glue), and a small bottle with a "sensitizer." Mix the two together (it turns bright green) and it becomes light sensitive. We then used a squeegee to spread that emulsion on both sides of the screen - smoothly covering the entire surface, front and back. That has to be put into a dark space to dry thoroughly. I created a little drying rack in the back corner of my workshop for that purpose, with a fan for air circulation, and I put an additional covering around it to ensure more darkness.

Once the screen is dry, it's time to transfer the image onto it. Here's where the process really starts to look like photography:

I cleared space on the top of my workbench, and clamped my work light about 12 - 15 inches above the surface. We put the screen down on the surface, placed the transparency of our artwork into the screen, and put a piece of glass on top to help hold the artwork flat against the screen. Set a timer, and turn on the light to expose the screen. The instructions in our kit gave us the exposure times, depending on the size of the screen, and the type of light source we were using. In our case, our exposure time was about 30 minutes.

So, here's what happens. Wherever the light shines on the screen, the emulsion gets "cured" or hardens into the screen. Wherever the light is blocked by the artwork, the emulsion remains softer and can be washed out, exposing the design in the holes in the screen. When the exposure is done, we took the screen to the sink with a sprayer and an old toothbrush - and washed the screen to open up the design. At that point, the screen is like a very detailed stencil, as already mentioned, and ready for printing.

Here's my Retro-kid with the screen inked up, and transferring the design onto a t-shirt . . .

. . . and the finished result.

We printed off a few t-shirts for ourselves and to give to friends. It was a fun project - and now that she knows the basics, she can experiment with more complex images and designs.

Okay - so, not exactly a bike-related project but I thought folks might enjoy reading about how we spent our last days of summer break.